Glory Tips About Are Breadboards Permanent

Breadboards

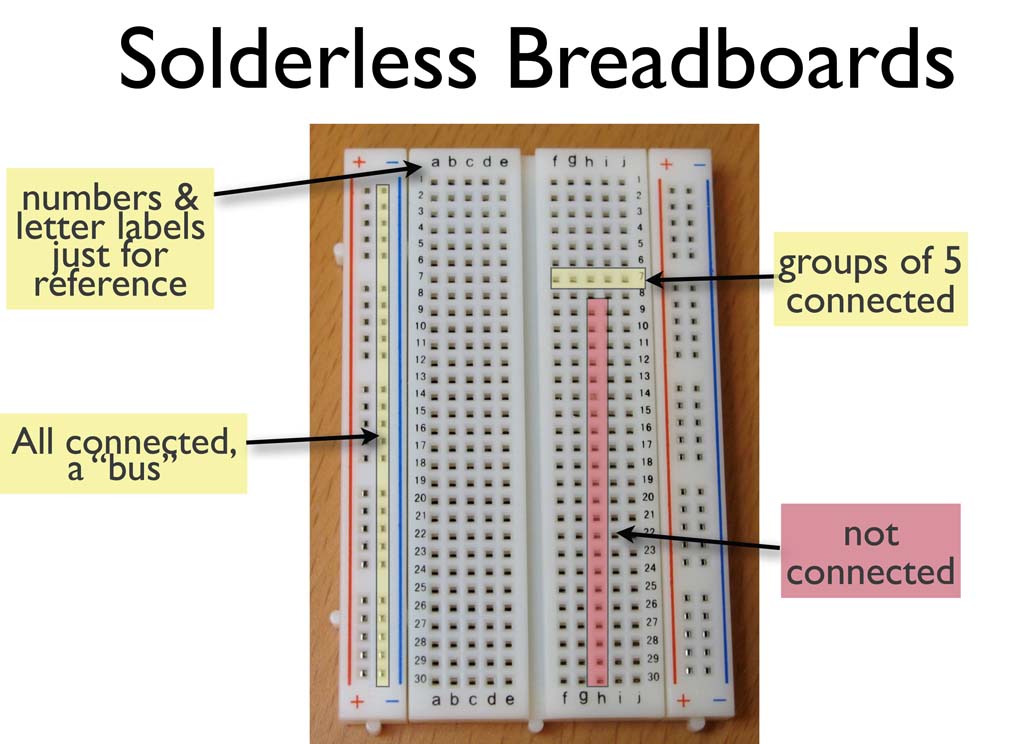

1. Understanding the Nature of Breadboards

So, you're tinkering with electronics, huh? Fantastic! You've probably stumbled upon the trusty breadboard, that solderless wonder that allows you to prototype circuits without setting your workspace (or your fingers) on fire. But a question likely crossed your mind: are these breadboards a permanent fixture in your electronic creations, or are they more of a fleeting romance?

The simple answer is: not really. Breadboards are designed for temporary prototyping. Think of them as the dating phase of your circuit design — a chance to test the waters before committing to something more serious, like a PCB (printed circuit board). They provide a convenient way to connect components without soldering, using little metal clips inside to make the electrical connections. Thats all pretty useful when you're still figuring things out!

The inherent design of a breadboard, with its push-in connections, means that over time, these connections can become loose or corroded. Repeated insertion and removal of components can wear down the internal clips, leading to unreliable connections. Imagine constantly unplugging and plugging your phone charger into the same outlet; eventually, it gets a little wobbly, right? Breadboards are similar in that regard.

Therefore, while you could technically leave a circuit on a breadboard indefinitely, it's generally not recommended if you need a stable and reliable long-term solution. It's kinda like building a house out of LEGOs impressive, maybe, but not exactly storm-proof. You might get away with it for a simple, low-power circuit in a controlled environment, but for anything more complex or destined for real-world applications, you'll want something more permanent.

Why Breadboards Aren't Forever

2. Durability and Reliability Concerns

Let's dive a little deeper into why breadboards and permanence don't exactly go hand-in-hand. One of the biggest issues is durability. Breadboards are typically made of plastic, and the internal metal clips are prone to wear and tear. Dust, moisture, and even the oils from your fingers can contribute to corrosion, affecting the conductivity of the connections.

Think of it like this: you wouldn't build a car engine out of cardboard, would you? (Okay, maybe as a fun project, but not to actually drive anywhere!). Breadboards serve a crucial purpose, but they're not intended for environments with extreme temperatures, humidity, or vibration. They are best suited for controlled lab or desktop settings. Trying to make a breadboard circuit work reliably in your car, or out in the garden is likely to induce headaches.

Another factor impacting reliability is the wire gauge used. Breadboards are designed to accommodate specific wire sizes (usually 22-26 AWG solid core wire). Using thicker wires can damage the clips, while thinner wires might not make a secure connection. Getting the wire gauge wrong is like wearing shoes that are too small or too big uncomfortable and ultimately not a good fit!

Finally, the nature of the connections themselves is a source of potential issues. The push-in connections rely on friction, and over time, that friction can decrease, leading to intermittent or unreliable connections. So if your project suddenly starts acting flaky after running fine for a while on a breadboard, loose connections are the first thing to check.

Diagram Of A Breadboard

Alternatives to Breadboards for Permanent Circuits

3. Moving Beyond the Prototype Stage

Okay, so breadboards aren't the best long-term solution. But what are the alternatives? Fortunately, the world of electronics offers several options for creating permanent or semi-permanent circuits, each with its own set of advantages and disadvantages.

First up: Perfboards! Perfboards are like breadboards' slightly more committed cousin. They're basically boards with a grid of holes, allowing you to solder components and wires directly to the board. This creates a much more robust and reliable connection than simply pushing components into a breadboard. Plus, you get to break out the soldering iron, which is always fun (as long as you're careful!).

Next we have stripboards (also known as Veroboards). These boards are similar to perfboards, but they have parallel strips of copper running along one side. This allows for easy creation of common connections and signal paths. However, stripboards require careful planning and cutting of the copper strips to create the desired circuit layout.

And last, but definitely not least, we have the ultimate commitment: printed circuit boards (PCBs). PCBs are custom-designed boards where the conductive pathways are etched onto the board itself. This creates a highly reliable and compact circuit. PCBs are ideal for mass production or for complex circuits where space is at a premium. Designing a PCB can seem daunting at first, but there are plenty of user-friendly software tools available to help you create your own custom boards, and services where you can get your design manufactured affordably.

Circuit Diagram Breadboard

Extending the Lifespan of Your Breadboard

4. Caring for Your Breadboard

Even though breadboards aren't forever, you can certainly extend their lifespan with a little TLC. Proper care and maintenance can help keep those connections tight and your circuits running smoothly (at least, for a while longer!).

Firstly, use solid core wire of the correct gauge (typically 22-26 AWG). Stranded wire can fray and cause shorts, and wires that are too thick can damage the breadboard's internal contacts. Think of it as using the right tool for the job — a screwdriver instead of a hammer, for example.

Secondly, avoid repeatedly inserting and removing components from the same holes. This can weaken the internal clips over time. If you need to make changes, try using a different set of holes. It's like rotating your crops in a garden to prevent soil depletion.

Finally, keep your breadboard clean and dry. Dust, moisture, and other contaminants can corrode the contacts. Use a soft brush or compressed air to remove any debris. And for goodness' sake, don't spill your coffee on it! Store your breadboards in a dry place when not in use. A plastic storage container or toolbox is a great option.

What Are Breadboards And Their Uses Breadboard Maker Pro

Frequently Asked Questions About Breadboards

5. Your Burning Breadboard Questions Answered

Let's tackle some of the most common questions about breadboards, so you can be a breadboarding pro!

6. Q

A: While technically you can, it's generally not recommended. Stranded wire can fray and individual strands can bend back upon insertion, leading to unreliable connections and potential shorts. Solid core wire is the preferred choice for breadboards.

7. Q

A: Use a soft brush or compressed air to remove dust and debris. For stubborn dirt, you can try using a cotton swab dipped in isopropyl alcohol. Make sure the breadboard is completely dry before using it again. Avoid using harsh chemicals or abrasive cleaners, as these can damage the plastic.

8. Q

A: Not exactly. Breadboards come in different sizes and configurations. Some have power rails running along the sides, while others don't. Some are made of higher-quality materials than others. In general, you get what you pay for. A higher-quality breadboard will typically have more reliable connections and a longer lifespan. But for basic prototyping, even a cheap breadboard can get the job done.